Harnessing Efficiency: Warehouse Automation in the Solar Energy Revolution

In today's rapidly advancing world, the solar energy sector stands at the forefront of sustainable innovation.

Read More

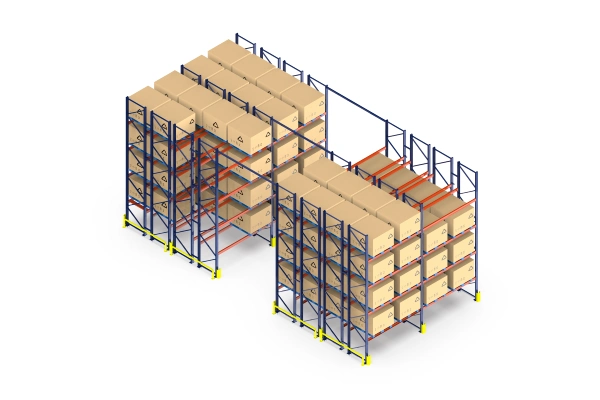

Double Deep Pallet Racking. Focused on both versatility and efficiency, our racking system strikes a perfect balance between accessibility to individual pallets and overall storage density. Unlike traditional racking systems where pallets are stored in single rows, our double-deep systems accommodate two pallets deep, similar to selective racking. This configuration significantly increases storage density while ensuring each pallet remains readily accessible and easily retrievable with minimal effort and time Our Double Deep Pallet Racking system is specifically designed for warehouses facing the challenge of high volume and limited space. This solution perfectly aligns with the inventory management strategy of FIFO (First In First Out) at two pallet batch levels and LIFO (Last In First Out) at the individual pallet level rotation. By optimizing storage density without compromising accessibility, our racking system maximizes warehouse efficiency and productivity. By condensing storage footprint while maintaining accessibility to inventory, Double Deep Pallet Racking addresses the evolving needs of modern warehouses seeking to maximize efficiency without compromising accessibility or safety.

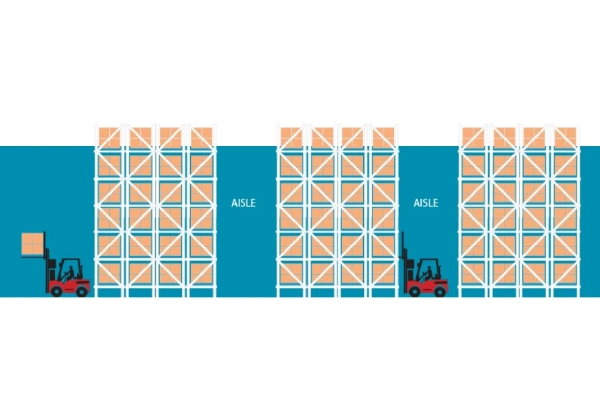

Basically, Double Deep Pallet Racking works by putting two pallets deep in one row. This means we don't need as many aisles to get to the stuff we need. By doing this, we can fit more pallets in the same space, which makes our storage area more efficient. Also, special forklifts with long reach can still get to each pallet easily, so we can always get what we need quickly.

One of the primary advantages of Double Deep Pallet Racking is its ability to accommodate a wide range of inventory types and sizes. Whether storing uniform pallets of goods or irregularly shaped items, this system provides flexibility to adapt to diverse storage needs. Additionally, its compatibility with various forklift types, including reach trucks and turret trucks, enhances operational versatility, allowing warehouses to customize their equipment to suit specific requirements.

In terms of operational efficiency, Double Deep Pallet Racking offers several key benefits. By reducing the number of aisles needed for storage retrieval, it minimizes travel time for forklift operators, resulting in faster picking and replenishment cycles. This streamlined workflow translates into improved productivity and throughput, enabling warehouses to handle increased order volumes with greater ease and efficiency. Moreover, the system's high storage density minimizes wasted space within the warehouse, maximizing the utilization of valuable real estate and reducing overhead costs associated with facility expansion or relocation.

Safety is paramount in any warehouse environment, and Double Deep Pallet Racking is designed with this principle in mind. Robust construction and durable materials ensure the structural integrity of the system, providing reliable support for stored inventory. Additionally, safety features such as pallet stops and backstops help prevent accidental pallet push-through or overhang, reducing the risk of damage to goods and injury to personnel. Proper training for forklift operators and adherence to established safety protocols further enhance warehouse safety and mitigate potential risks associated with storage and retrieval operations.

Implementing Double Deep Pallet Racking requires careful planning and consideration of various factors, including warehouse layout, inventory characteristics, and operational requirements. Collaborating with experienced warehouse design professionals can facilitate the development of a tailored storage solution that maximizes the benefits of Double Deep Pallet Racking while addressing specific challenges and constraints unique to each facility.

Conclusion

In conclusion, Double Deep Pallet Racking represents a cost-effective and efficient storage solution for warehouses seeking to optimize space utilization and enhance operational productivity. By doubling storage capacity within existing footprint and streamlining storage and retrieval processes, this system enables warehouses to meet the demands of modern logistics and fulfill customer orders with greater speed and accuracy. With its versatility, safety features, and potential for customization, Double Deep Pallet Racking offers a compelling value proposition for warehouses looking to future-proof their storage operations and remain competitive in an increasingly dynamic marketplace.

Craftsman Storage Systems takes pride in offering a versatile solution that adapts to various warehouse layouts and operational needs. Our Double Deep Pallet Racking system is seamlessly integrated into warehouse spaces, whether installed against a wall or in conjunction with another double-deep section behind it. This configuration results in a remarkable 65% increase in floor area utilization, making it an ideal choice for warehouses aiming to make the most of their available space.

Loading and unloading pallets from our Double Deep Pallet Racking system is made efficient and hassle-free with the use of double reach or deep reach lift trucks. This ensures smooth and streamlined operations, even in warehouses with high throughput requirements.

Craftsman Storage Systems understands the diverse storage requirements of warehouses, particularly for products with high rotation rates or identical characteristics that necessitate multiple pallets per reference. Our Double Deep Pallet Racking system provides the perfect solution for efficiently storing and managing such products, thereby enhancing overall warehouse organization and inventory management.

In short, our Double Deep Pallet Racking provides a complete solution for warehouses that want to save space while still being able to easily access and organize items. Our racking system is designed to be flexible and works well with different ways of managing inventory. It's a great investment for warehouses looking to improve how they work and get more done.