Pallet Flow Racks

Pallet flow racks, also known as Live Pallet Racking, are a hybrid of gravity flow conveyors and racks. Live Pallet Storage Racks are the ideal option for high-density, FIFO pallet storage, particularly for batch storage of high-volume goods.

Tap to View

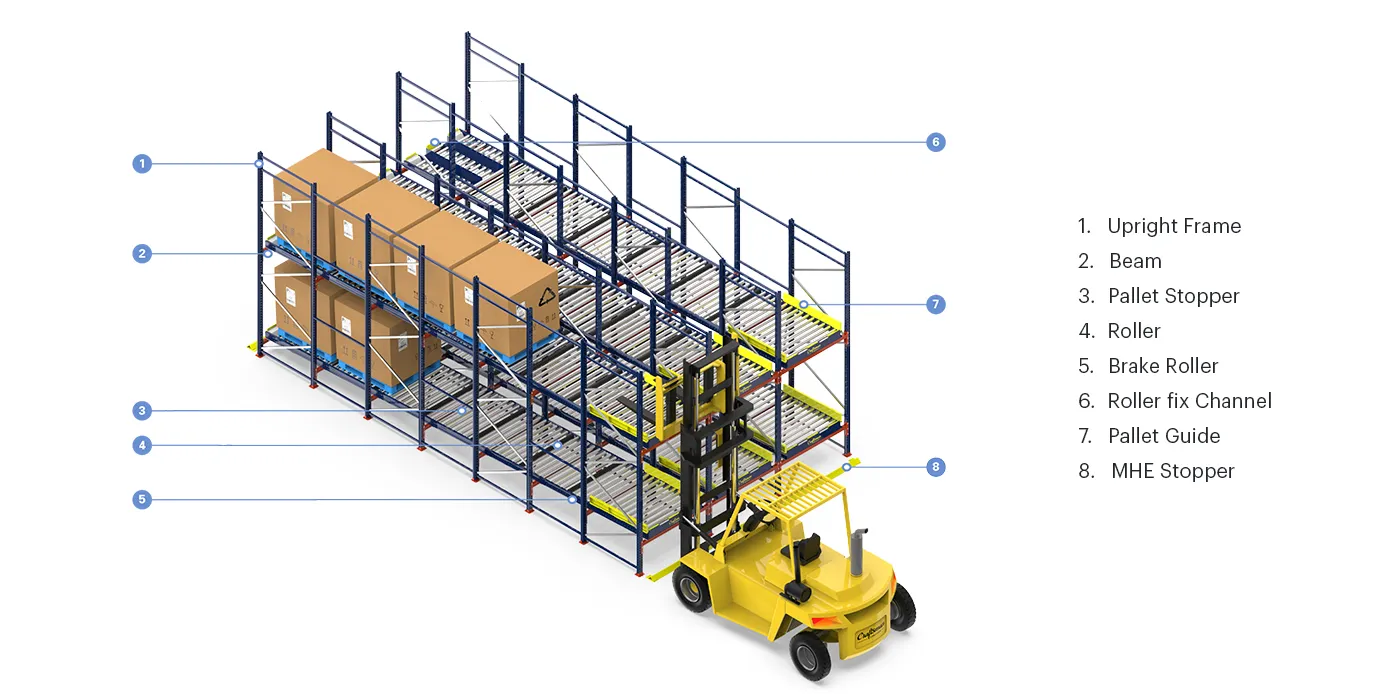

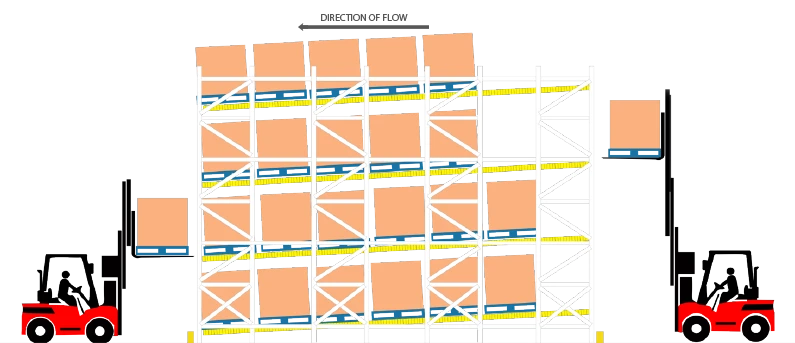

Flow Rack employs elevated rails in conjunction with dynamic components such as rollers, conveyors, and brakes, all within a rack-supported structure. Pallets are therefore placed onto the raised end of the flow system, thereby transforming the pallet to the other end. View More

Our Pallet Flow Racks can be customized to meet your specific storage requirements to adapt to your needs by delivering the pallets at the front. The roller conveyor, for example, can be customized with brake rollers and a variety of roller spacing to match your unit load. Our Pallet Flow Rack comes with a range of safety accessories such as pallet guides, MHE stopper, column guards, row guards, etc. View Less

Side View

Product Gallery

Advantages

- Based on First-In, First-Out (FIFO) inventory control, the live pallet storage racks are the most effective solution when products have an expiry date or when batch and product series monitoring is necessary

- Live pallet storage racks are highly efficient in terms of space and volume in the warehouse

- Live racking system offers higher productivity through separation of supply and picking

- Live racking system is an ideal solution for non-stackable pallets and high volume items

- Last-In, First-Out (LIFO) inventory control allows the system to be used as pushback racks

- Live racking system offers high-density storage