Warehouse Management System

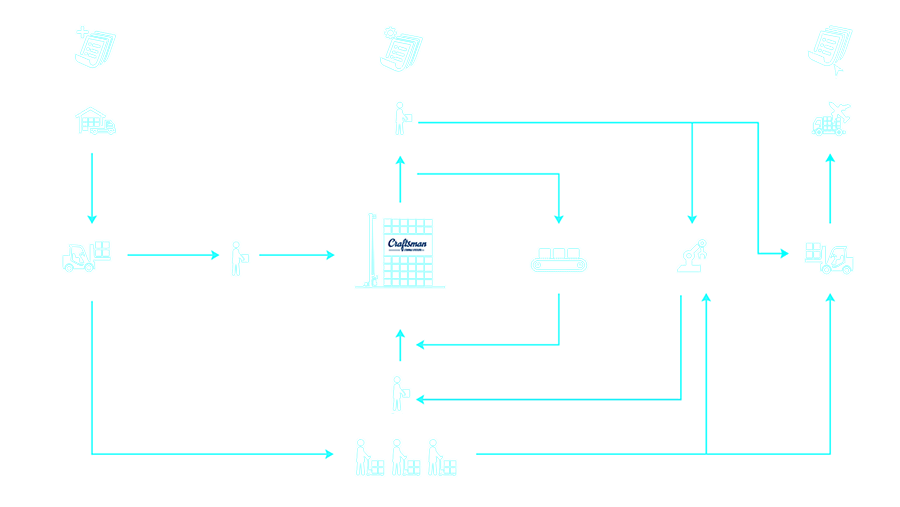

The automation of a warehouse, or part of it, involves automating its management. A Warehouse Management System is used to plan, organise and optimise your warehouse operations. The WMS Software aims ensure that you can provide the right goods at the right time while optimising both efficiency and costs.

Craftsman’s Warehouse management software is made to help users improve the efficiency of tracking inventory and supplies in a storage system. Through our WMS various processes like Picking, Sorting, Transfer are made possible. The WMS can be a stand-alone service or it can be integrated with an Enterprise resource planning (ERP) or Supply Chain Management (SCM) software, thereby significantly enhancing user experience. Advanced reporting features within the software helps managers analyse performance of the operation as a whole and find areas of improvement. The WMS software designed inhouse is customer specific i.e. configurable to the users needs, rather than requiring you to change your business to fit the software.

WMS System helps to manage a Warehouse like a Conductor of an Orchestra by

Synchronizing all warehousing activities starting from Receiving up to Dispatch & Truck

Loading.

It leverages advanced data capture using Barcode labelling / RFID tagging and related

technologies.

Leads to a Robust & Load balancing system, every-step-of-the-way.

Helps to Synchronize activities towards phased prioritized picking through Wave

Management

Can trigger extensive Alerts for operators, for required manual actions/interventions.

With a well-integrated WMS System

Helps to provide visibility of inventory of Goods through-out the entire Warehouse life cycle.

Supports in significantly reducing the operating cost by shortening order-fulfilment cycles.

Boosts productivity by using Task Interleaving features for high throughput.

Reduces inventory costs implementing MOQ and automated replenishment.

Improves inventory accuracy.

Basic functions of a WMS Software

Management of Inbound Goods

Management of Inbound Goods

The reception process is responsible for managing the entry of the goods from different sources into the warehouse i.e. purchases from suppliers, transfer of goods between centres, production orders, customer returns, etc. Errors in receiving, unlike most other errors in your warehouse, have a ripple effect. The entry of goods starts with the reception process, whereby the diversity, the quantity, the characteristics and the condition or quality of the goods entering the warehouse, to become stock, are accurately controlled. To do this, the information collected is compared with the order received from the ERP for higher inventory accuracy.

Location Allocation

Location Allocation

Managing where the goods should be deposited follows the 'location processes', which are governed by previously established rules and strategies. These processes are responsible for administering the order in which goods are placed in the warehouse, determining the best location according to their type, characteristics, dimensions, etc. It properly distributes product locations in the different aisles to ensure an adequate response to outgoing operations. Grouping and various processes are governed by the system hence reducing human work-load. Our WMS intelligently directs warehouse operators, AS/RS stacker cranes, shuttles and conveyors to put away material in stock locations that optimise storage and reduce material handling and fulfilment costs.

Three strategies to place stock in warehouse:

- Location through Rules & Strategies

- Management of replenishment & Consolidation tasks

- Cross Docking

Inventory Management

Inventory Management

Stock management is a very prominent feature in the WMS because through it, real-time visibility of the location, the status, the amount and characteristics of the warehouse stock is secured. The administration is performed with the help of an ERP. All functions of the WMS can be integrated into the rest of the company’s management system which enables the Real time inventory management.

Inventory management features are:

- Real time Storage Usage

- Supports Bar code

- User Friendly experience

- First in First out (FIFO)

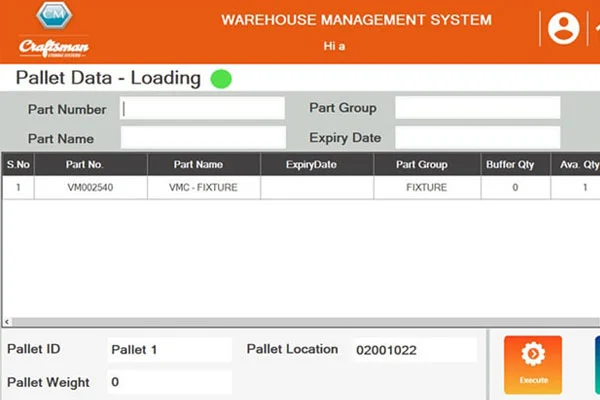

Our system constantly tracks the ageing of the inventory and enables First in First out (FIFO) logic to be implemented seamlessly. The software can also highlight non-moving and slow-moving stock, which empowers users to make informed decisions. Perishable goods with a pre-determined expiry date can be tracked in the WMS. No matter your business size, our WMS is built to outgrow you. Craftsman’s WMS is configurable and scalable, it will meet the present and future demands projected by your business.

Order Processing, Picking & Dispatch

Order Processing, Picking & Dispatch

On-time and accurate shipments are key to meeting the perfect order experience which is expected by todays customers. In addition to managing the receipt and location of goods, the management system also controls the dispatch of goods. The WMS deals with processes like, the preparation of the orders that are shipped to customers, transfers to other warehouses or returns to suppliers. In short, they are responsible for the exit and drops in the warehouse stock via operations like picking, Packing, Sorting orders and their dispatch. The best pick and dispatch practices of industry leaders are imbibed in our software thereby acting as a guide during these processes, ensuring hassle free operation and enabling the fastest-error-free order fulfilment which wins the customer. The goods for dispatch are then delivered in the right sequence to the respective loading docks using an intelligent Dock Management Systems (DMS). The delivery confirmation is then automatically captured and fed to the ERP as a proof of delivery.

Data Backup and Security

Data Backup and Security

We understand the importance of data security and our software runs on the latest encryption protocols. All data is stored locally and can be backed up remotely using Cloud services. Security is provided through user passwords and Access Authority Levels. Authorization for data access can be granted or revoked by accessing our user rights management feature. Special privileges can be granted on a need basis for system administrators, auditors, management personnel.

Advantages

- WMS Software Optimize Tasks

- Highly Adaptable

- Boost Productivity

- Inventory Tracking

- Increase Inventory Transparency

- Stock management

- High space occupancy

- Optimises storage locations and flows

- Improves labour productivity by providing real time data

- Cost-reduction through Resource Optimization

- Increased transparency

- Configurable & scalable