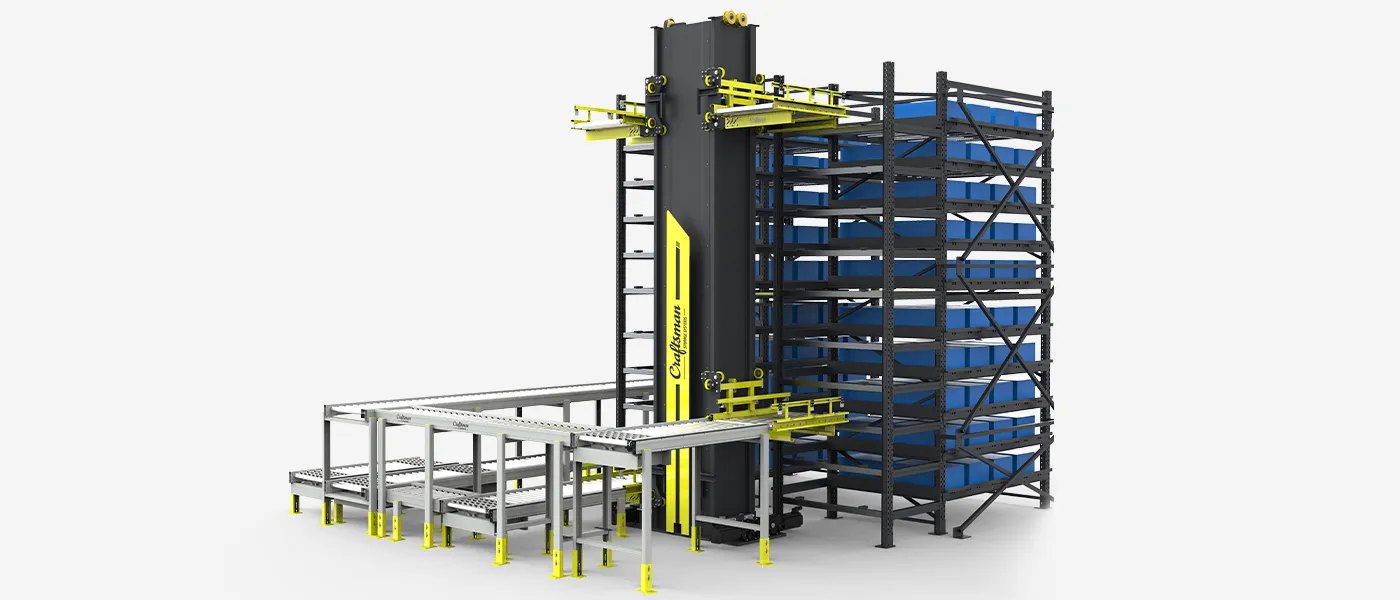

Sorting and Conveying Systems

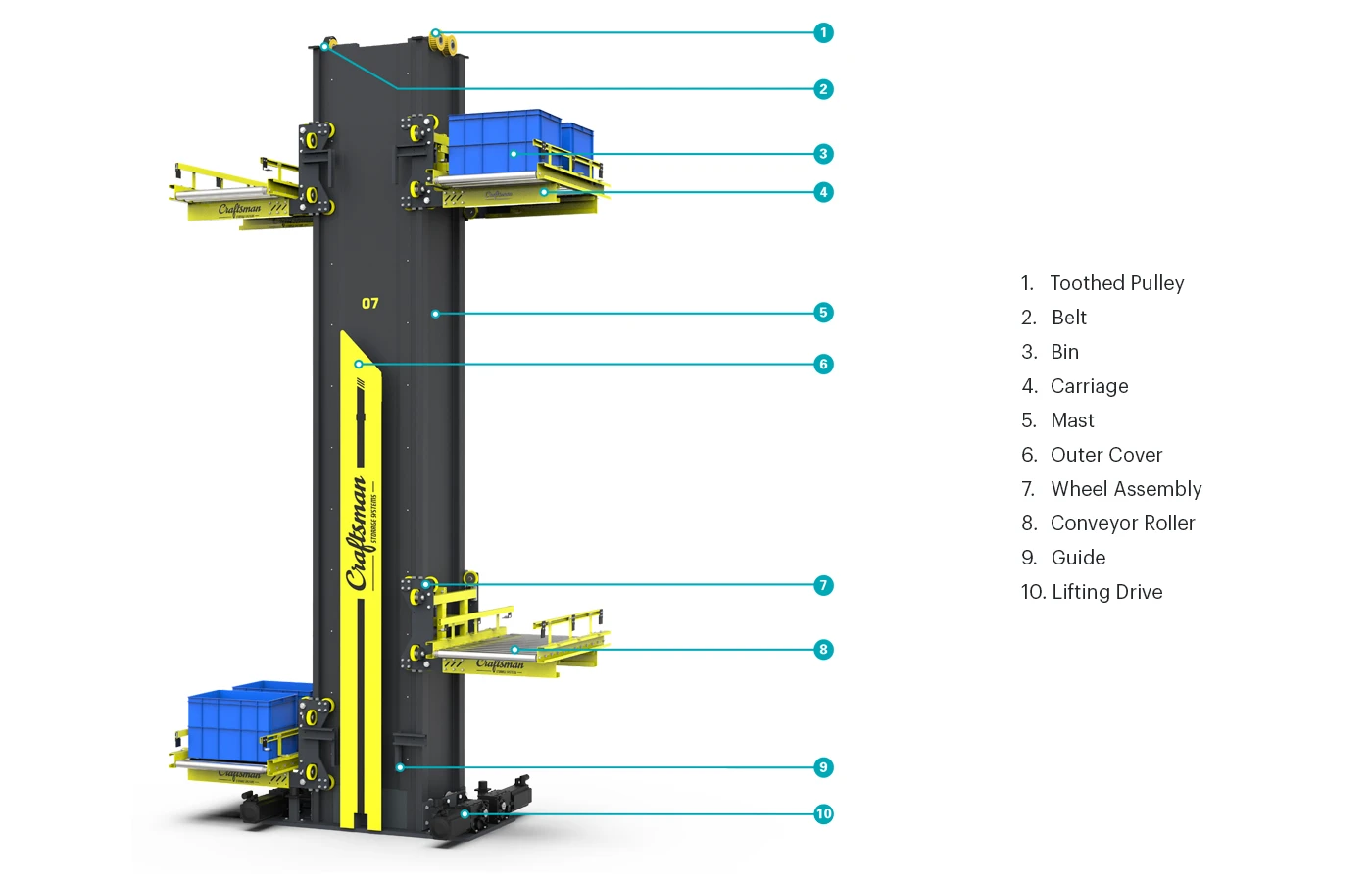

From warehouse automation to production facilities, Craftsman Mini-load ASRS conveyor systems are used for a broad range of applications. Mini-load ASRS conveyor system has a modular transporting system for bins, totes, small carton boxes, and products weighing up to 50 kg. The use of a driving system and presence detection systems enabled by mechanical or optical sensors allow boxes to be moved under controlled conditions to the desired positions

Tap to View

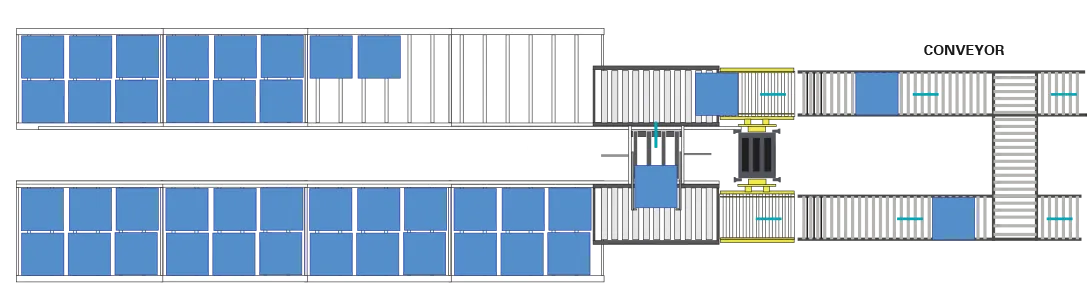

The functions of the Mini-load ASRS conveyor system includes conveying, sorting, buffering, merging, diverting, lifting, and lowering. Our conveyor systems are scalable to the needs of its users and adjustable for future expansion. The conveyor systems are controlled through a PLC-based intelligent warehouse control system (WCS). The WCS operates in synchronization with the warehouse management system (WMS) to ensure seamless delivery in the required sequence. Multiple systems can be stacked together for even higher throughputs.

Top View

Product Gallery

Advantages

- Low-noise operation

- Low maintenance

- Suited for cold storage

- High reliability

- Standardized spare parts