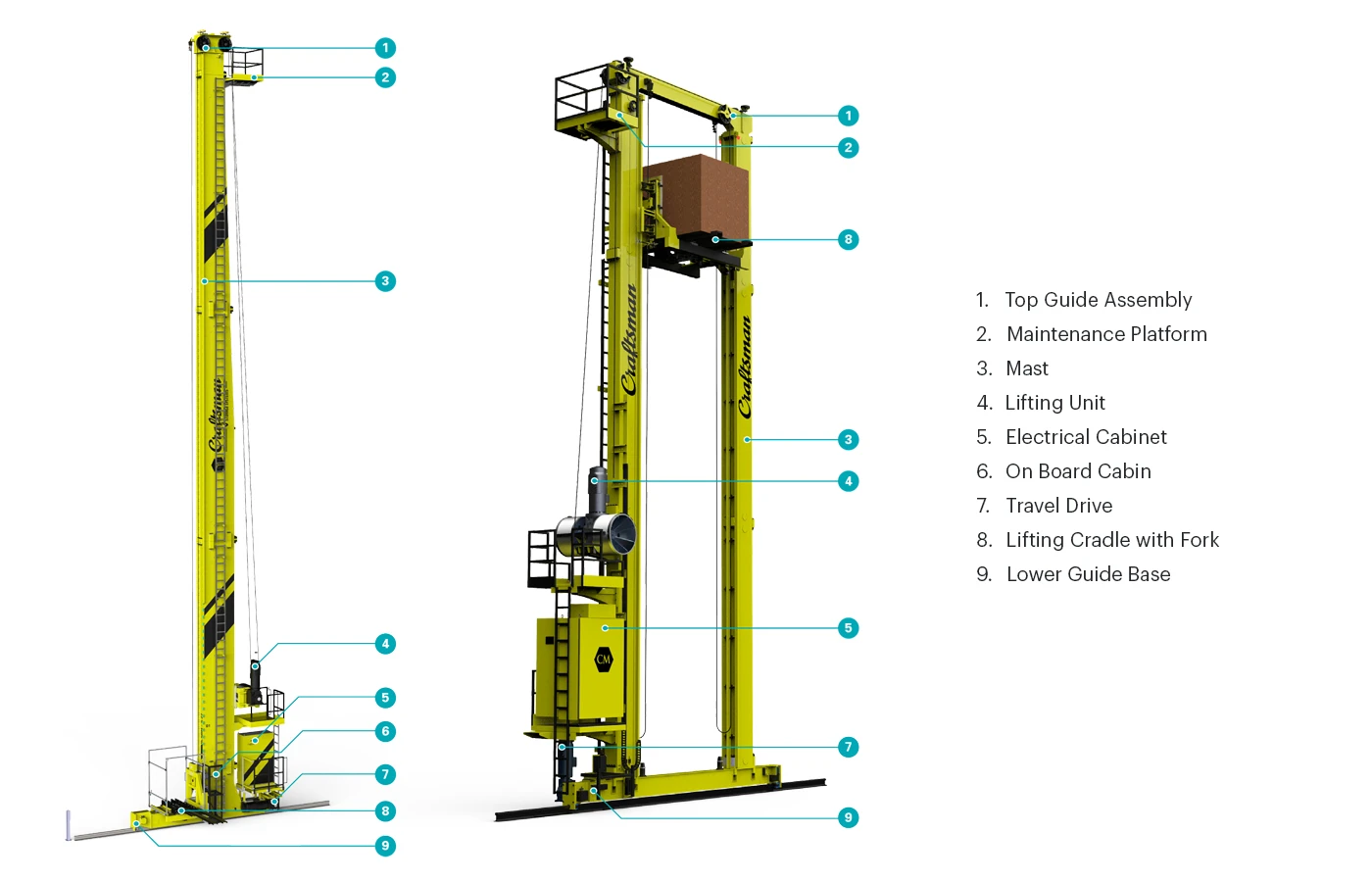

Pallet ASRS Crane

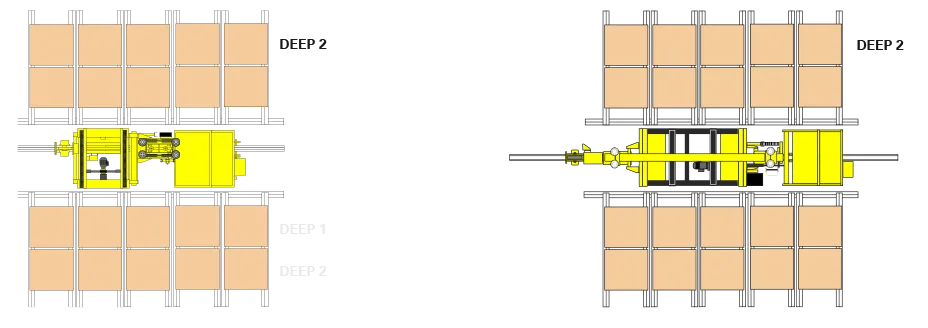

Automated storage and retrieval machines that run on rails, with a single or double mast frame depending on the requirements of the system. Equipped with telescopic forks, for the storage and retrieval of pallets from single or double-deep racks, making this solution is highly adaptable to a wide range of materials and handling needs.

Tap to View

AS/RS Stacker cranes- Designed according to FEM specifications, our AS/RS stacker cranes are individually engineered and customized to suit customer-specific storage in terms of pallet dimensions, weight, and throughput requirements. Up to 40 pallets In & Out per hour per crane. To overcome vibrations in the mast during operation, anti oscillation devices and tampering programs are implemented.

Top View

Product Gallery

Advantages

- Guaranteed pallet throughput

- Optimum Sequencing of material

- Safe and efficient pallet handling

- Single & Double deep for optimum pallet selectivity

- Multi-deep achieved with Craftsman Shuttle

- Reliability Ensured

- Controlled Inventory

- Accurate inventory ERP sync

- 24/7 Availability

- Cost saving in labour and space