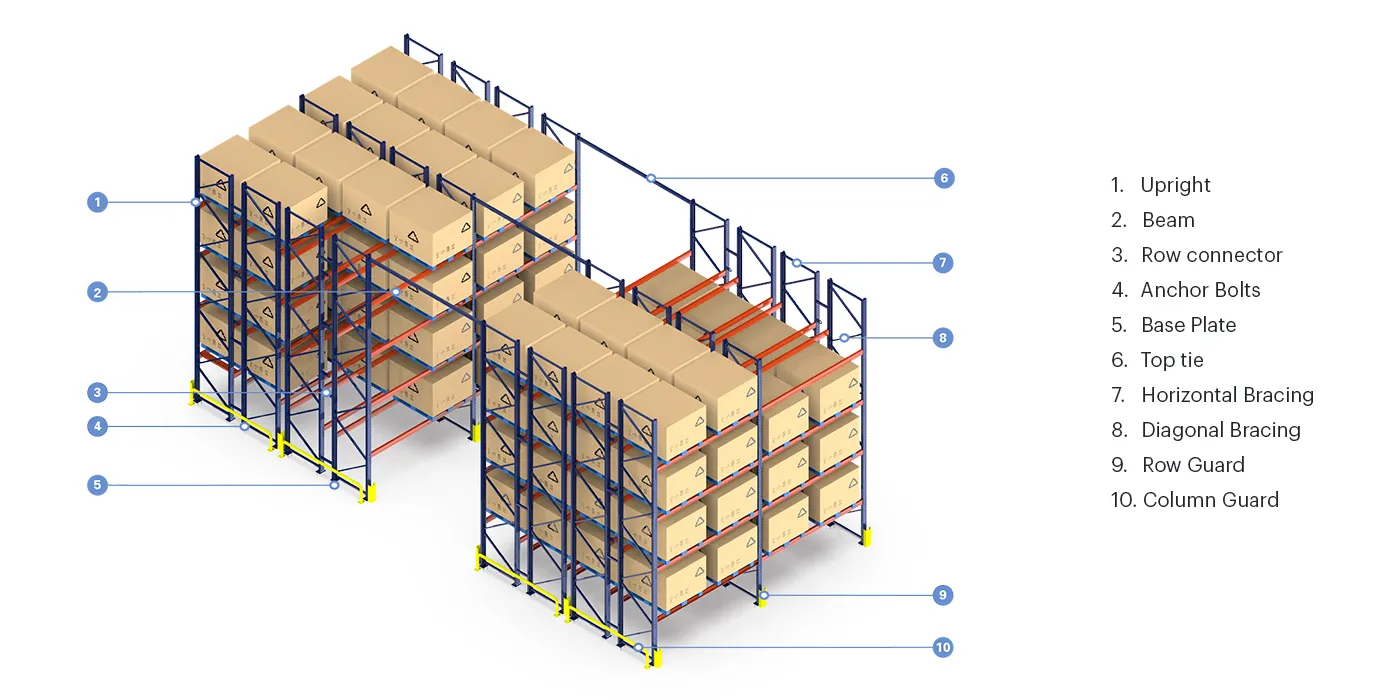

Double Deep Pallet Racking

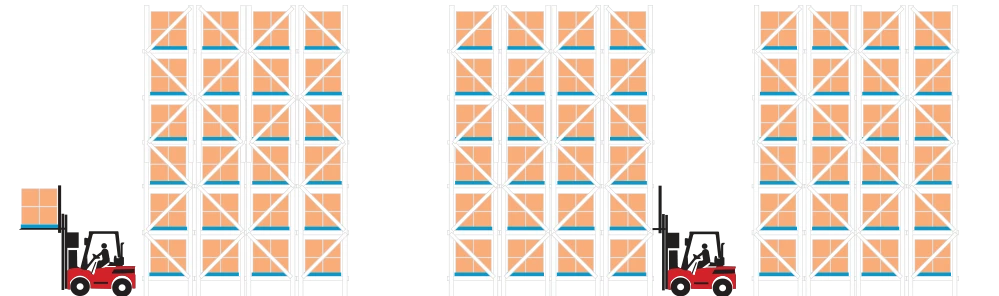

When compared to Single Deep Selective Pallet Racking, Double Deep Pallet Racking enhances warehouse density by up to 40% by allowing two pallets to be placed i.e., One behind the other to offer 50% selectivity.

Tap to View

It is a versatile and efficient racking solution with a good balance between pallet selectivity and pallet storage density. Pallets are placed two rows deep instead of one in double-deep racking systems, similar to selective racking, thus resulting in a higher storage density. The pallets are still accessible simply and rapidly. By default, our framework is designed to be installed against a wall or in conjunction with another double deep-section behind it, resulting in a 65% increase in floor area. View More

Double Deep Pallet Racking systems are ideal for warehouses with high volume and limited space that use the FIFO (First In First Out) at two pallet batch levels and LIFO (Last In First Out) at individual pallet level inventory rotation. Pallets are loaded and unloaded from our system using double reach or deep reach lift trucks. Our Pallet Racks are ideal for keeping products that are identical or have a high rotation rate and require more than one pallet per reference. View Less

Double Deep

Product Gallery

Advantages

- More efficiency, eliminating unnecessary aisles and maximizing the use of available space

- Double Deep Racking Systems are adaptable to any type of unit load

- Highly efficient and robust system with easy assembly and regulation of load levels

- The racking framework can be effortlessly configured, modified and extended at low investment costs

- An economical alternative to drive-in racking

- Ideal for homogeneous or identical product warehouses

- Saves time and effort in handling unit loads, generating fast stock rotation

- Design of the framework enables its reconfiguration or extension according to the changing storage needs in future

- Working aisle and the height of the racks can be customised according to Material Handling Equipment, pallet sizes and the height of the warehouse

- Double-deep configurations can also be established in automated warehouses through stacker cranes with telescopic forks