Multi-Level Shuttle System: Enhancing Automated Storage & Retrieval

Smart storage systems that save space and simplify your workflow.

Step into the future of automated warehousing with Craftsman Storage’s Multi-Level Shuttle System — a high-performance automated storage and retrieval solution (ASRS) engineered for speed, precision, and scalability.

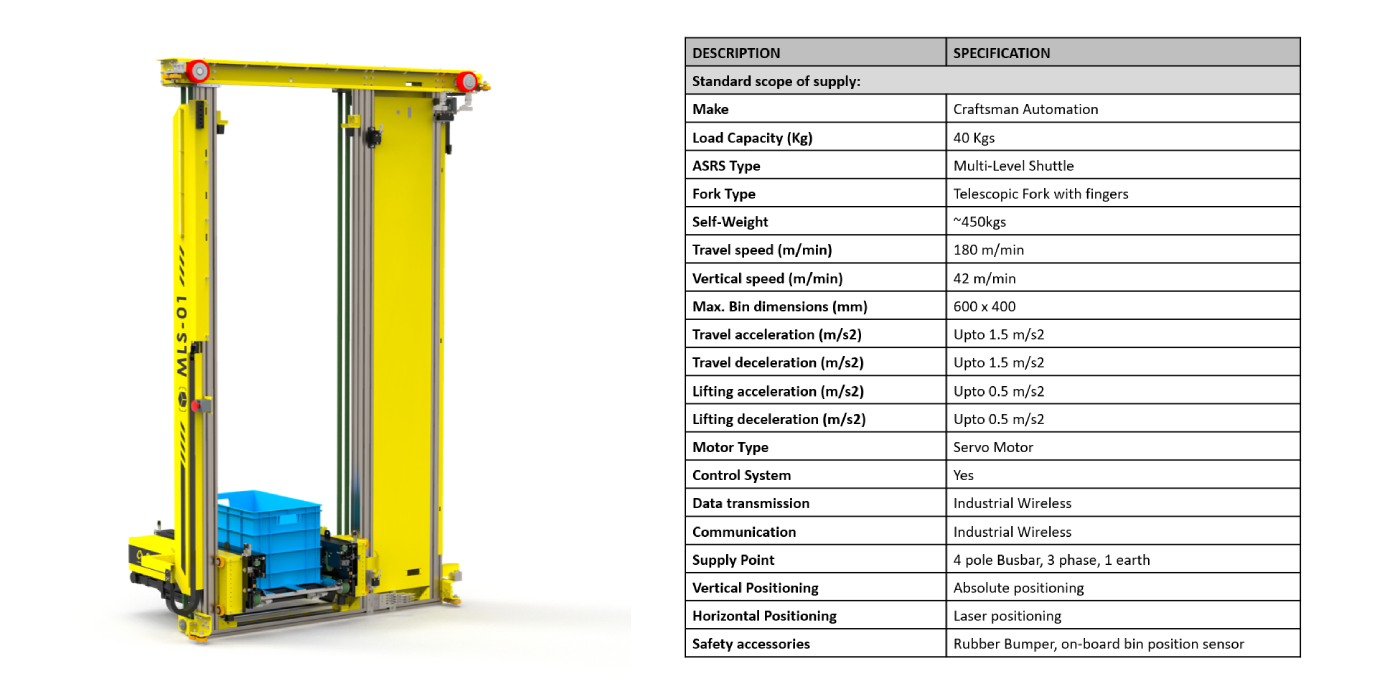

The Multi-Level Shuttle system by Craftsman Storage Systems is a high-throughput, automated storage and retrieval solution designed for bins, totes, and small cartons.

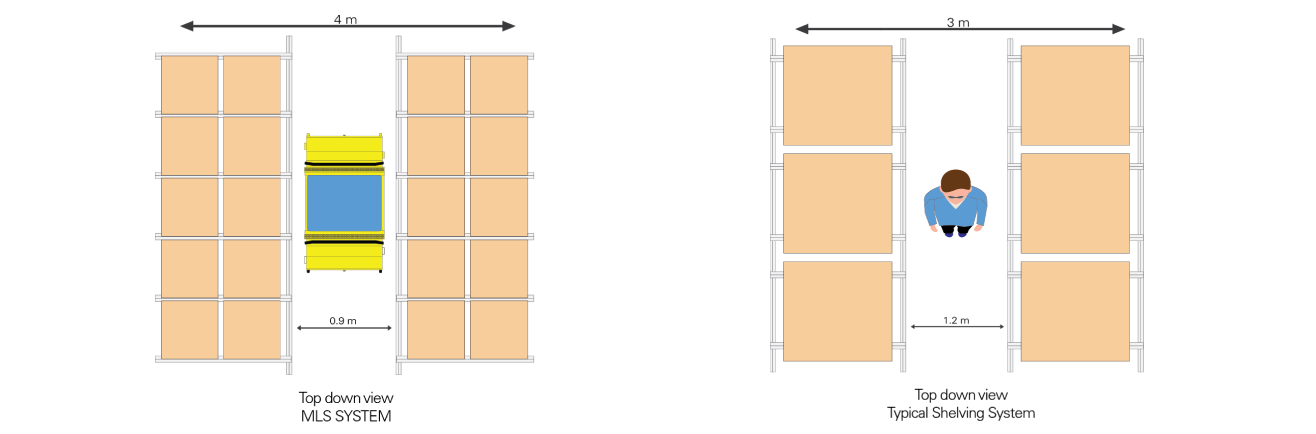

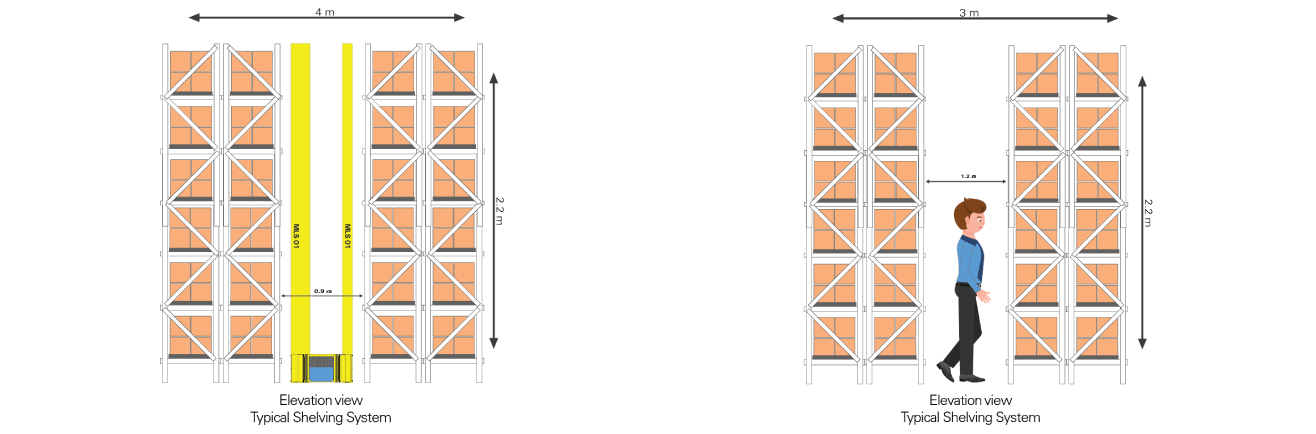

With its modular architecture, the MLS maximizes vertical and horizontal space utilization, making it ideal for dynamic warehouse environments with diverse SKU handling and rapid order fulfillment needs.

Whether you're running a distribution center, warehouse, or manufacturing unit, our shuttle system is designed to move large volumes of materials quickly and efficiently — all while saving space, reducing costs, and boosting productivity.

Tap to View

Automated bin handling system-

The maximum weight MLS can handle is 40Kg/ bin with below mentioned bin dimensions.

Tap to View